The UV-100N is a UV spectrometer designed for measuring the quantity and quality of ultraviolet light sources, utilized in various applications such as semiconductor manufacturing, industrial curing, and sterilization. These applications employ different types of UV sources including UVA, UVB, and UVC for their specific purposes.

Ultraviolet (UV) light, unlike general lighting, presents complexities due to the absence of fixed specifications, standards, and industry norms typically found in general lighting applications.

The efficacy of UV light applications depends on various factors including wavelength compatibility with different industrial uses, material properties, and process duration.

Therefore, the accurate characterization of UV sources becomes paramount, encompassing considerations such as wavelength, intensity, quantity, and duration.

These elements constitute the essence of UV light applications and represent significant challenges within the UV light industry

| Sensor | CMOS Linear Image Sensor |

| Wavelength Renge | 250 to 430 nm |

| Wavelength Date Increment | 1 nm |

| Spectral Bandwidth | Approximately 1nm (Half Bandwidth) |

| Measurement Range |

UVA*1,4: 315 to 430nm / 0.25 to 500 mW/cm2 UVB*2,4: 280 to 315nm / 0.3 to 200 mW/cm2 UVC*3,4: 250 to 280nm / 0.2 to 300 mW/cm2 |

| Accuracy |

± 5% (10 to 500 mW/cm2) ± 19% (0.2 to 10 mW/cm2) |

| Stray Light | -25 dB max.*5 |

| Integration Time Range | 1 ms to 2,000 ms |

| Digital Resolution | 16 bits |

| Capture Function | One time / Continuous |

| Measuring Capabilities |

|

UV100N is focused on Spectral Analytics of UV Light Sources:

The UV100N is equipped with a sensor head with a thickness of approximately 20mm, enabling it to meet the spatial constraints of various applications for measuring light sources and test samples

The design features a separate screen from the probe, ensuring real-time monitoring of data during measurements without the need to wait until the completion of the measurement to confirm results.

In addition to the standard 20cm optical fiber, custom versions ranging from 30 to cm can also be provided to accommodate various measurement application requirements.

In this fast-paced era, in many UV light source applications, users are not only concerned about the immediate quality of the light source, but also prioritize its long-term stability and reliability.

Many processes cannot tolerate production losses due to critical UV light source component failures.

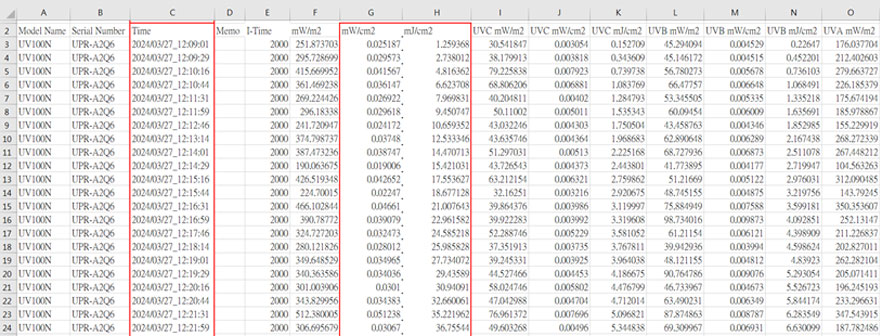

Therefore, the UV-100N offers the longest continuous measurement capability, enabling users to monitor the quality or stability of light sources across various intervals. It serves as the ideal tool for daily inspection of light sources at the production line's end.

UV curing devices, can be classified into two light source system : UV mercury lamps/halogen lamps and UV LEDs.

UV mercury lamps/halogen lamps:Have a wider range of wavelengths, providing better effects for specialized UV adhesives or materials with poor surface drying properties. However, since these types of light sources also emit visible light and infrared.

UV LED:Provide a single wavelength based on the LED chip used. They have the advantage of lower temperature, instant on/off without the need for gating mechanisms, and longer lamp life. However, due to their narrow wavelength, they may have less effective curing results for certain UV adhesive materials. Therefore, UV LED light sources are often used in combination with mixed wavelength configurations.

Standard light sources (visible light andultraviolet light) in UPRtek.

Perform maintenance and proofreading every year (ITRI)